The project introduced two sets of PST14000 energy-saving and environmental-friendly spray dryer from HLT DLT, "Energy-saving, environmentally friendly, intelligent, and small footprint" with a daily output of 800 tons of powder.

The wasted heat recovery energy-saving system S.H.A.R.E. can efficiently utilize wasted heat to achieve further energy conservation and emission reduction while reducing nitrogen oxide emissions. The comprehensive energy saving can reach 10%; compared with traditional water-coal slurry boilers, it can save 10-15% energy.

2 DHD-EM5 series five-layer dryer, 2 "4.0 energy efficiency benchmark digital era, DFC - Alpha firing kilns and supporting equipment. Single line capacity 30,000m²/day

The equipment runs smoothly with uniform products and excellent quality.

The "4.0 Energy Efficiency Benchmark Digital Era" continues to adhere to high standards and high starting points, giving full play to the advantages of modern equipment and highly automated firing kilns.

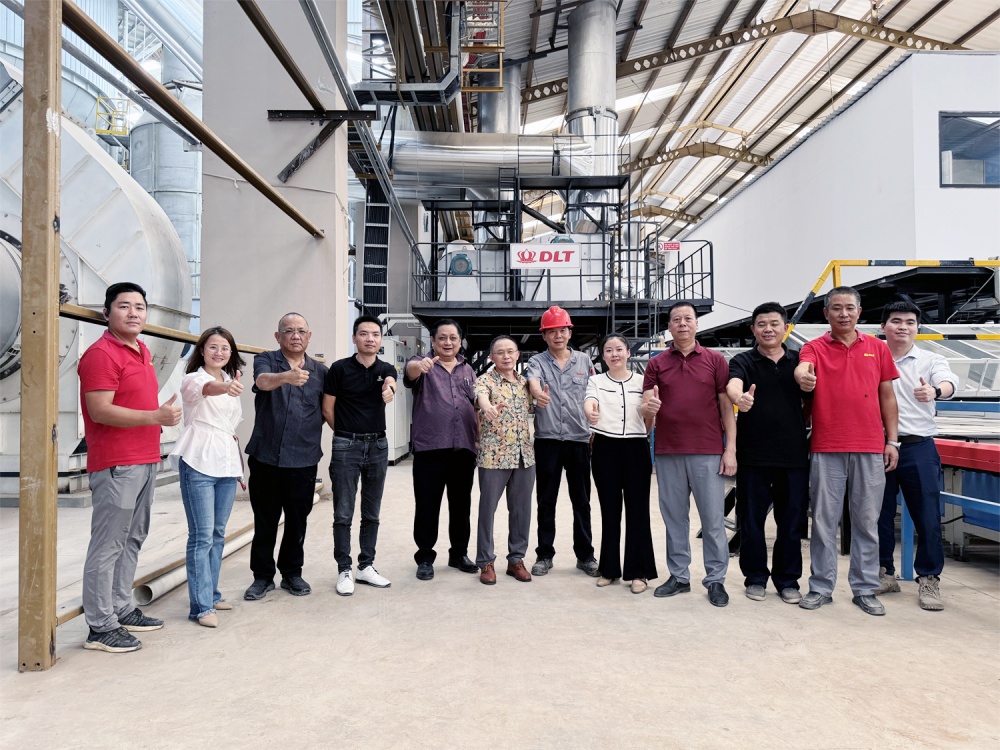

Entering into the ceramic sector business for the first time and successfully putting it into production is the courage of SPS Group and the witness of the strength of HLT DLT.